The 21st annual, 2011 Southern Appalachian Man and the Biosphere Conference was held at the Renaissance Hotel in Asheville on Nov. 15-17. During these three presentation-packed days of discussing the social and economic uses, current trends, and future demands of South Appalachian forests, speakers covered a wide array of eco-centric topics.

Presenter John Swann caught my attention: He represents the entrepreneurial spirit that has shaped Western North Carolina’s local movement and endowed the region with a thriving cottage-industry culture. People like him keep Asheville sustainable, fresh and no corporate cut-out of just Any City, USA — even if the efforts often go without lavish monetary rewards. (Some of you might recall that Swann co-founded the original Green Life grocery in Asheville.)

John Swann’s Maple Creek Farm is located above 3,000 feet, ranging from 3,200 to almost 4,000-foot elevation in Yancy County. He bought the 106-acre farm six years ago with the “intentions of retiring up there maybe having a retreat.” After surveying the property, he realized he had about 500 sugar maple (Acer saccharum) trees. These trees like it cold, and WNC lies on the southern edge of where they’ll grow, and even then, the maples prefer the shady north side of the mountain and higher elevations.

“We decided to see if we could get a little maple operation going,” said Swann.

Maple trees take about 30 years to mature before they’re ready, and then they’re only 11 or 12 inches in diameter and ready for one tap. At 18 inches two taps can be drilled in; at 23 inches, three taps, and at 36-42 inches, four taps. The entire farm boasts only one or two trees worthy of the four-tap crown. Maple trees go dormant during the winter, and the sap sinks into the roots. When the trees thaw in the spring, the sap rises toward the branches. “What we are looking for ideal maple syrup weather is a freezing at night and thawing during the day,” said Swann.

Maple syruping should be a simple process. Drill a hole, drive in a tap, and the sap flows. Theoretically. “The first year we did it the old fashion way and found out how you don’t do it,” said Swann. “We started off with just a handful of trees and collected the sap in buckets, and we found out really quick why [most producers] don’t do that anymore. It’s an awful lot of work, especially if you’re hiking up and down the hills with rocks and brambles,” said Swann. As far as Swann knows, he is the only commercial producer of maple syrup in North Carolina.

The first year, Swann and family tapped six or eight trees and yielded about a quart of syrup. “The first year we did it the old fashion way and found out how you don’t do it,” said Swann. The second year, they put tubes in place, which are attached to the taps to channel the sap down to a central processing station they call the Sugar Shack. They tapped about a 100 trees and got almost 18 gallons of syrup. The third year, Swann recalls deciding, “We’re going to do it right.”

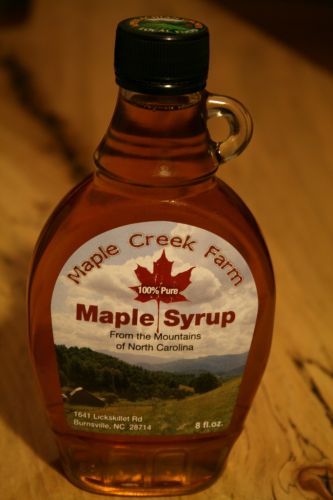

They added 200-300 more taps. With five weeks of good weather, production reached almost 100 gallons of syrup. Each gallon can be sold for about $168 retail, and they only pack in 8 ounce and 12 ounce bottles. With the excitement of a good season, Swann went ahead and upgraded with more taps, lines, and storage facilities, only to get frozen out of all but two days of flow for the next season (two springs ago). The result was only less than 20 gallons of syrup. Last spring, the weather didn’t cooperate, along with a few other problems, reducing the harvest season to 10 days and around 20 gallons of syrup.

“If we could regularly hit even close to 100 gallons a year of production, it would be profitable; it would be well worth doing. Unfortunately, the yield has been so miserable that I figure our break even is about 30 gallons. So I can’t exactly say this is a shining model of economic feasibility. It’s not. It’s a hobby at this point. If the weather cooperates, we have the capacity to do roughly 150 gallons, if we get four to six weeks’ worth of weather. It’s been very much less than that. It’s been a little disappointing. We’re going to keep trying,” said Swann.

Even if the money isn’t flowing, the experience has been savory in other ways. “Once you start cooking [boiling the sap down to syrup], you keep cooking until you run out of sap. So if you got 1,500 gallons of sap … you can run 48 or even 72 hours straight. It’s a challenge. It is a lot of fun to be there at 3 in the morning cooking sap. I don’t get tired doing it. It’s just fun,” said Swann.

Here’s a short video of Swann describing how once the cooking starts, it’s nonstop, even at 3 in the morning.

This February 25 and 26, Maple Creek Farm will be holding their annual maple tour out on the farm. In the past, they’ve sold their entire limited amount of syrup during that tour. “We’ll have something to boil down on the 25th of February, even if it’s just water,” said Swann. For more on the farm and this special top of the season tap and tour, visit http://maplecreekfarm.net/

Jonathan Poston is a writer based in Asheville N.C. Photos courtesy of John Swann and Maple Creek Farm.

Before you comment

The comments section is here to provide a platform for civil dialogue on the issues we face together as a local community. Xpress is committed to offering this platform for all voices, but when the tone of the discussion gets nasty or strays off topic, we believe many people choose not to participate. Xpress editors are determined to moderate comments to ensure a constructive interchange is maintained. All comments judged not to be in keeping with the spirit of civil discourse will be removed and repeat violators will be banned. See here for our terms of service. Thank you for being part of this effort to promote respectful discussion.